- Rebar Chairs & Spacers

- Rebar Placing & Fixing

Safety Netting / Barrier Netting

Try our scaffolding accessories!

BASE JACKS

COMBI-NUTS

SCAFFOLDING COUPLERS

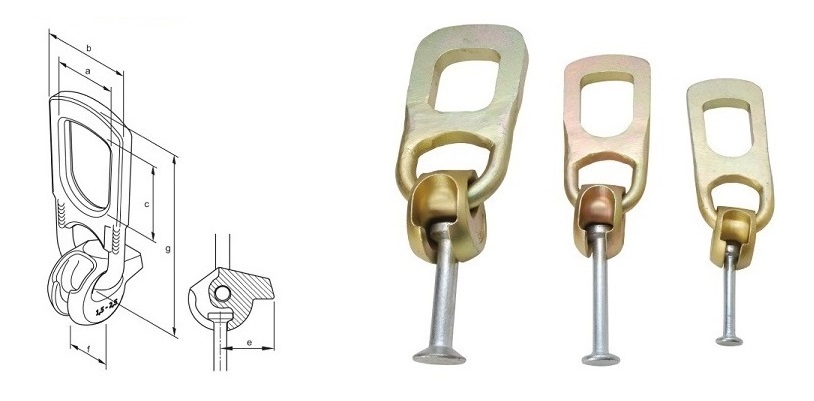

Spherical Head Lifting Clutch - Tested for 3 x working load

The capacity loads are axial with breakage safety factor equal to 5

for all types of lifting clutches (1,3 ton up to 32 ton). The Spherical

Head Lifting Clutch comes in 6 different load groups. 1,3 to 32 ton, to

suit the load carrying range of ALL TYPES OF LIFTING ANCHORS with spherical-heads.

Instructions for the use of Spherical Head Lifting Clutches

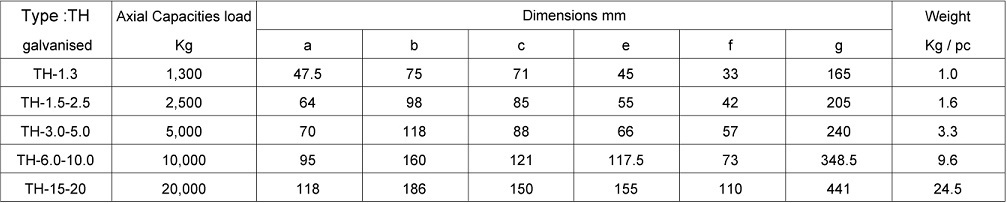

Lifting and Turning

The Spherical Head Lifting Clutch is constructed

in a way that an unintended coupling off (even

without tension by a lifting device) is impossible.

On lifting, attention must be paid that the lip is

in the direction of the tension being applied.

The Spherical Head Lifting Clutch is suitable for lifting in all directions (axial, diagonal, and lateral tension).

On turning of units, special attention must be paid to the lip position of the Spherical Lifting Head Clutch. The lip must always be in the be in the direction of the Tension (See picture 3).

The Spherical Head Lifting Clutch is suitable for lifting in all directions (axial, diagonal, and lateral tension).

On turning of units, special attention must be paid to the lip position of the Spherical Lifting Head Clutch. The lip must always be in the be in the direction of the Tension (See picture 3).

Releasing the Spherical Head Lifting Clutch

To release the Spherical Head Lifting Clutch

the tension on the clutch must be removed.

Thereafter the Spherical Head Lifting Clutch

can be released, by turning the handle in the

opposite direction to the lip (See picture4).

Corrosion Protection

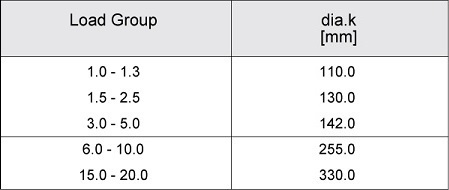

Corrosion protection can be increased by installing the

Spherical Head Anchor in a sunken position. The recess

former must be installed to ensure the functionality

of the Spherical Head Anchor according to these installation

instructions and must have the minimum dimentions in accordance

with table 2 here below.

Dimensions for sunken assembly

The Spherical Head Lifting Clutch counts as a lifting device

and is therefor subject to regular inspection (at least once

a year -

BGR 600 Section 2.8).

This must be executed by an expert and it is the responsibilty

of the user.

Particular safety procedures and regulations must be followed to extend the lifespan and durability of the Spherical Head Lifting Clutch. The right hook size and form should always be checked and be ensured.

Particular safety procedures and regulations must be followed to extend the lifespan and durability of the Spherical Head Lifting Clutch. The right hook size and form should always be checked and be ensured.